FIND THE RIGHT COOLER FOR YOUR COMPRESSOR MACHINE

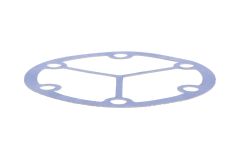

Compressor machines are dependent on their coolers to perform at an adequate level, making them an essential component. These crucial pieces of equipment keep the compressed air or gas at the optimum temperature, which is critical for achieving optimal performance and avoiding excessive heating. Compressor coolers are able to effectively get rid of the heat that is produced during the compression process by making use of a variety of cooling methods, such as air, water, or oil. Compressor coolers are often constructed as heat exchangers with fins or tubes, and their design aims to increase the contact area between the heated fluid and the air or liquid that is in the surrounding region. This improved contact makes for a more efficient heat transfer, which in turn helps to keep the operating temperature at the ideal level. Compressor coolers, whether they are utilized in industrial settings, refrigeration systems, or air compressors, play an important function in boosting the overall efficiency of these equipment and prolonging the service life of these devices.

The removal of heat from the compressed air or gas, performed by compressor coolers, is the fundamental function of these devices, which helps to avoid the potentially damaging effects of overheating.

A compressor cooler contributes to the dependability and durability of compressor systems by successfully regulating the heat created during compression, which is one of the byproducts of compression. Because of their involvement in removing excess heat, the machines are able to run within the temperature range that has been shown to be optimal for performance while also reducing the likelihood that they would be damaged or fail.

WHAT PURPOSE DOES A COOLER SERVE IN A COMPRESSOR MACHINE?

In order to guarantee the dependability and durability of compressor equipment, coolers are essential. They contribute to minimizing component wear and tear, lowering the likelihood of system failures, and extending the equipment's lifespan by limiting overheating. Customers may feel secure using this reliability feature, which is crucial for commercial and industrial applications. Coolers help the compressor machine operate at its best by managing the temperature. It is possible to increase efficiency, minimize energy use, and improve overall performance when compressed air or gas is kept at the proper temperature. For industrial applications, this may lead to cost savings and higher production. Coolers are made to effectively disperse the heat produced during compression. They use specialized heat exchangers, such as finned or tubular designs, to increase the fluid's surface area in contact with the air or liquid around it. This characteristic of efficient heat movement enables efficient cooling and minimizes the accumulation of excessive heat.

WHAT SHOULD I LOOK FOR IN EDMAC COOLERS

At Edmac Europe, we put a lot of effort into keeping our promise to be your go-to partner for all of your compressor and vacuum needs. We are confident in recommending the more affordable Edmac alternative range as the course you should take because we are aware that you are solely concerned with what is best for your business. Because we take quality very seriously, we make sure that all of our Edmac compressor parts meet or even exceed the OEM standards. Edmac Europe can underline that they provide a selection of coolers that work with different compressor machine models, including both their own brand and original equipment manufacturer (OEM) compressor parts. It is simple to change or update the cooling components as necessary thanks to this adaptability, which guarantees that consumers can find the proper cooler to meet their unique compressor system. On the Edmac website, you may find a number of brands, including Boge compressor coolers, Kaesar compressor coolers, Beko compressor coolers, Ingersoll Rand compressor coolers, Parker coolers, and more.

The value of our alternatives is assessed, tested, and examined by authorities in the field. Our aftermarket compressor coolers will maintain your machine's optimal performance for the same period of time as their OEM equivalents at a lower cost. Do it anyhow; don't be afraid. You won't regret doing it in the future.

WHY ORDER COOLERS AT EDMAC EUROPE?

Finding replacement components for your compressor machine is what we do. Every day, all day long, we work on this. In our inventory, there are 10,000 references to both genuine and aftermarket goods. Our best-selling items are kept in stock so that we can give you a timely service. We also made it easier to locate parts. Choose your component after entering your reference, which might be a brand name, OEM reference, Edmac part number, or even just a portion of it. Comparing our Edmac replacements to the original equipment manufacturer part is easy. Then, all you have to do to get going is click "add to cart"! Easy.

CHECK OUT OUR FULL RANGE OF COMPRESSOR SPARE PARTS TO COMPLETE YOUR MAINTENANCE

We have a wide variety of compressor parts to keep your commercial equipment operational. You can find a range of coolers for Ingersoll Rand, Boge, CompAir, Kaeser, Almig etc.

REPLACEMENT COMPRESSOR COOLERS CAN BE ORDERED ONLINE FROM EDMAC EUROPE AND DELIVERED TO YOU.

It is possible to order the delivery of either an OEM compressor cooler or an Edmac compressor cooler. Our team takes great care in preparing your package and we ensure that it will be delivered promptly. Placing an order is the only requirement. Our team takes care of all other tasks.

24336 Renner Special 56 / Semi-synthetic, 5 LitersSKU: 3004802992In stockYour savings: 9%€99.14 €90.22

24336 Renner Special 56 / Semi-synthetic, 5 LitersSKU: 3004802992In stockYour savings: 9%€99.14 €90.22